Among SIG Sauer collectors and enthusiasts, West German SIGs occupy a position of reverence. Whether or not West German SIGs are superior to the more modern US-made SIGs is a matter of debate best left for others to rehash. All I’ll say on the subject is that I’ve personally visited SIG’s manufacturing facilities in Newington, New Hampshire and have seen first-hand the passion, attention to detail, and commitment to quality of the US-based employees, and would have no reservations owning any of their current-production-era examples. Staring through the glass cases at the full-line up SIG’s Pro Shop in Exeter, New Hampshire, I wanted one of each!

I must, however, admit that West German SIGs always have, and always will, hold a special place in my heart. Unfortunately for those of us who share that fondness, market values for original, serial number-matching, well-preserved West German SIG pistols keep climbing. But if you’re feeling a little adventurous, there is still at least one way to enjoy the West German SIG ownership experience without breaking the bank. For your consideration, I present the SIG Sauer P6:

West German SIG Sauer P6

SIG Sauer P6 History

When a service pistol receives approval by the West German government for sale to police (Polizei) or military units, it receives a numbered “P” designation. For years, the Polizei relied on the P1 (Walther P38), P2 (SIG P210), and P3 (Astra 600) service pistols, until the mid-1970s when the West German government adopted a number of new requirements. They wanted the next generation of service pistols to feature a DA/SA action, 9×19 Luger chambering, 8 round magazine capacity, and the ability to decock the pistol via an external safety or decocking lever. Walther quickly bolted a decocker onto their P38 and received the P4 designation, but nothing else was “modern” about it so the P4 never really took off. Walther later submitted an updated design to meet all the new requirements and received the P5 designation. SIG Sauer submitted a slightly modified version of its P225 and received the P6 designation. Heckler & Koch’s new PSP (Polizei-Selbstlade-Pistole or “police self-loading pistol”) was designated the P7. Mauser had also designed a pistol to meet the updated German requirements, but because it never went into production, it never received an official “P” designation. Among the three new pistols that did, the Walther P5 was unpopular and the H&K P7 was expensive, so the vast majority of German law enforcement agencies purchased the SIG Sauer P6. An estimated 40,000-ish SIG P6s were in circulation before the Polizei retired the SIG P6 in 2000 in favor of the less-expensive polymer-framed H&K USP (which received the P8 designation) and the Walther P99Q.

SIG Sauer P6 with German Polizei jacket

SIG P6 vs. P225 Differences

There are four main differences between SIG’s standard P225 and the Polizei-desginated P6: mainspring weight, external markings, feed ramp geometry, and a notched hammer spur. Let’s look at these differences a bit more closely.

P6 vs. P225 Mainspring Weight

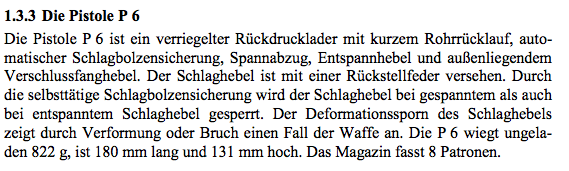

The most noticeable difference between the SIG P6 and P225, at least for your trigger finger, is the P6’s heavy 24 lb mainspring (item #33 in the parts diagram below):

SIG Sauer P225 parts diagram

On the P225, SIG used the same standard 18-19 lb mainspring that it used in the P220, P226, P228, and much later the P229. Those extra pounds of trigger resistance on the P6 helped ensure that if a West German cop wanted to pull the trigger…. he really had to want to pull the trigger.

P6 vs. P225 External Markings

The easiest way to tell a P6 from a P225 is its external markings. Here’s a visual comparison of markings on the SIG P6 (on top) vs. the P225 (on bottom):

SIG Sauer P6 (top) and P225 (bottom)

The SIG P225’s external markings look identical to its P220, P226, and P228 siblings of the same era: proof marks on the slide chin, full serial number, “P22X,” and “Made in W. Germany” marking on the slide, etc.

The P6 was marked “P6” to the right of the ejection port. Initials indicating the police department to which the pistol was sold were also stamped on the right side of the slide. For example, a P6 sold to the Nordrhein-Westfalen state police would be marked “NW” while one issued to the federal criminal police would be marked “BKA.”

A date code in the form of M/YY was also stamped on the right side of the slide, near the muzzle end. A P6 proofed in January of 1980 would be marked “1/80.” The last three digits of the pistol’s serial number would also appear on the slide under the date code, while the full serial number would be stamped on the frame.

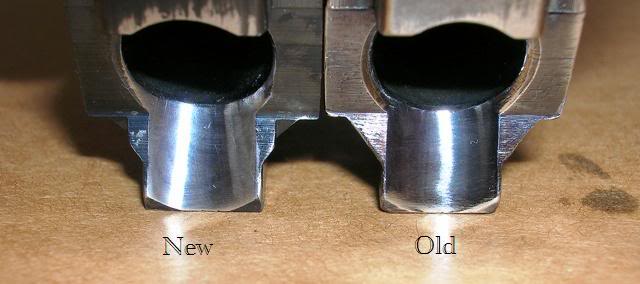

P6 vs. P226 Feed Ramp

SIG P6 pistols with date stamps earlier than 6/89 (June 1989) had slightly different feed ramp geometry than the standard P225. The original P6 feed ramp was designed for the full-metal jacketed “ball” ammunition used by German police at the time, but also seems to do fine with smaller 115-grain jacketed hollow-point rounds. However, the original P6 often had trouble feeding modern jacketed hollow-point rounds larger than 124-grain, so SIG updated the P6 feed ramp in 1989 to better support JHP ammo. Swapping in a P225 barrel or having the P6’s feed ramp re-profiled to the 1989 specs will fix the issue with larger JHP rounds.

Side-by-side new vs. old SIG P6 feed ramps

P6 Hammer Spur Notch

Of all the differences between the commercial P225 and Polizei-issue P6, none has been more widely disputed than the strange-looking notch cut into the P6’s hammer’s spur:

SIG P6 with hammer spur notch

I’ve heard the notch referred to as a lanyard hole where Polizei officers could secure the gun to their belts.

I’ve heard stories of Polizei armorers looping a metal wire around the grip and into the notch to secure the gun in storage, as well as plastic beaded ties in the same location designed to break in the event the hammer travels rearward to indicate that the gun had been fired.

I’ve even heard jokes about it being used as opener for German beer bottles.

But the craziest explanation I’ve heard for the P6’s strange little notch is that it was intentionally designed to bend or snap off as a visual indicator in the unlikely event that a German police officer just happened to drop his gun… and it just happened to land exactly on the tip of the hammer! Yeah, right. As if the Germans would be crazy enough to demand such a strange design element in their service pistols.

It turns out the Germans are crazy enough to demand such a strange design element in their service pistols.

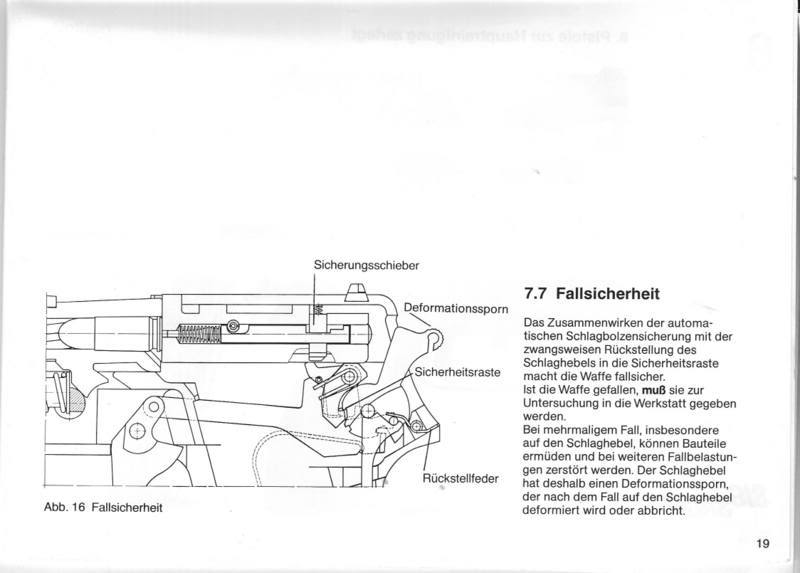

With all the various opinions regarding that notch circulating around the Internet, I set out on a mini-Mythbusters episode. I started with the P6’s owner’s manual, which includes an additional section 7.7 (on page 19) that doesn’t appear in the P225 manual:

SIG P6 Owner’s Manual Section 7.7

The section name “Fallseicherheit” (pronounced fahl-ZIG-gher-hite) translates literally to “fall security,” referring to the system of security features in the pistol’s design that render the gun safe in the event it’s dropped. The German text from page 19 of the owner’s manual reads:

Das Zusammenwirken der automatischen Schlagbolzensicherung mit der zwangsweisen Rückstellung des Schlaghebels in die Sicherheitsraste macht die Waffe fallsicher.

Ist die Waffe gefallen, muß sie zur Untersuchung in die Werkstatt gegeben werden.

Bei mehrmaligem Fall, insbesondere auf den Schlaghebel, können Bauteile ermüden und bei weiteren Fallsbelastungen zerstört werden. Der Schlaghebel hat deshalb einen Deformationsspor, der nach dem Fall auf den Schlaghebel deformiert wird oder abbricht.

Google Translate does a semi-decent job of decoding it to:

The interaction of the automatic impact bolt safety device with the forced resetting of the impact lever into the safety catch makes the weapon safe.

If the weapon has fallen, it must be put into the workshop for inspection.

In the case of several cases, in particular on the impact lever, components can become fatigued and destroyed in case of further impacts. The impact lever therefore has a deformation pore, which is deformed or broken after the fall onto the impact lever.

That’s still confusing, so with a few of my personal tweaks to the translation (Google doesn’t do well with firearms terms), I think this makes more sense:

The interaction of the automatic firing pin safety combined with the forced retraction of the hammer to its safety intercept notch makes the weapon drop-safe.

If the weapon is dropped, it must be taken the armory for inspection.

If dropped repeatedly, particularly on the hammer, components can become worn and destroyed (making them useless) against further drop-related impacts. The hammer therefore has a deformation spur, which is bent or broken if dropped on the hammer.

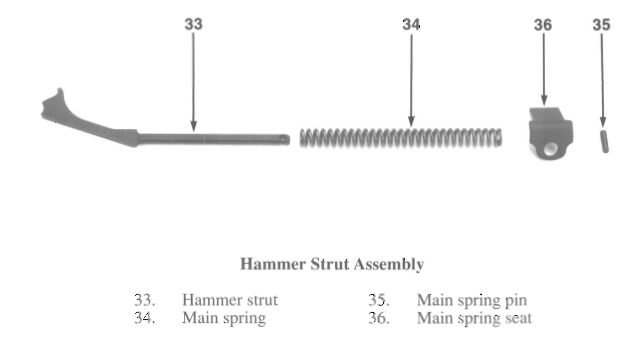

There you have it, folks. It says right there in the manual that the P6’s hammer notch exists so the hammer spur will bend or break off if the P6 is dropped on its hammer. Still not convinced? Check out the 2001 German Federal Border Police manual Arbeiten zu Studium und Praxis im Bundesgrenzschutz (which translates to “Work to Study and Practice in the Federal Border Police”). Coincidentally, it also happens to be page 19 of that manual that discusses the SIG Sauer P6 service pistol:

Again, Google Translate’s version wasn’t very helpful, so here’s my version that combines my terrible German with looking up part names on German parts diagrams. The phrases in parentheses are not in the original text, but added by me for clarity:

The P6 pistol features a locked breach with short recoil blowback action, automatic firing pin safety, double-action trigger, decocker, and external slide catch. The hammer has its own reset spring. Due to the hammer’s independent safety mechanism (hammer intercept notch), the hammer is locked regardless of whether the internal safety mechanisms are engaged (the hammer can only strike the firing pin if the trigger is pulled). The hammer’s deformation spur will bend or break to indicate whether the weapon has been dropped. The P6 weighs 822g (1.8 lbs) unloaded, is 180mm (7 inches) long and 131mm (5 inches) high. The magazine holds 8 rounds.

But was it really that common for the P6 to be dropped? That question is answered by a former Polizei officer who carried the P6 on duty:

The P6 has a internal safety-block who is locking the firing pin unless the trigger releases the hammer. When we changes from P1 to P6 in late ’79/early ’80 we also change from the old well known hard shell holsters in WWII-style to more modern, so called “fast draw holsters”. The first generation of this holsters were rotten s*** and many P6 fall down during the training. Some of them at the hammer. Result: damaged firing pins. So all hammers were modified to absorb the energy and/or indicate a possible damaged firing pin. P225 for the civilian market didn’t have this modification. When I began my career in 1980 at the West-Berlin police academy, the first weapon in our training program had to be the pistol – but the solution for the problems shown above needed 2 1/2 years, modified hammers and new holsters. So we were trained with our MPL, G3, MG3 and some weeks before we get the P6 with the obsolete P1.

There you have it: a first-hand account that early P6 pistols did fall out of poorly-designed police holsters, land on their hammers, and damage internal parts. For the purposes of my mini-Mythbusters episode, the “myth” that the P6’s notched hammers are actually indicators for a dropped and possibly damaged pistol is “confirmed.” Two manuals and a first-hand account agree on its purpose.

As for whether the notches were ever used as lanyards, I’m gonna call that myth “busted.” First, there’s no evidence or first-hand account I could find of that ever happening. Lanyard attachment points certainly did exist on pistols of that era, but they were always located at the base of the grip. Attaching a lanyard in a location that could pull against the hammer and possibly cock the action seems completely ridiculous — especially for safety-obsessed Germans.

I’m not quite ready to call the myth about wire or plastic loops through the hammer notch “busted,” though I’m not yet willing to call it “confirmed,” either. Based on a handful of accounts of former Polizei (as well as an account from a family member of a Polizei) who swear up and down that they saw P6 pistols stored in this manner in Polizei armories and vehicle lock-boxes, I’m going to call that myth “unconfirmed… but plausible.” While it’s certainly not the stated intent in any manual, I don’t find it difficult to believe that some inventive German police armorers may have taken advantage of the available notch to further “secure” the hammer in certain situations. Again, that’s not in any manual and I’d need a photograph to upgrade this myth above “plausible,” so in the unlikely event that any former Polizei reading this have an old photo of a P6 stored in this manner, please email it to me. Otherwise, this use case is “plausible,” but the original intent and only confirmed reason for the P6’s hammer notch is as a visual indicator of a dropped pistol.

A Flood of Surplus P6 Pistols

In 2000, when the Polizei moved to the newer H&K USP (P8) and Walther P99Q, they eventually rounded up tens of thousands of P6 pistols and removed them from service. They then sold literally thousands of them to Century International Arms in Georgia (city… not state), Vermont who imported them to the US and sold them as surplus police returns to civilians — usually for between $250-$300. For purposes of their import mark (which was required to be stamped on every P6 they sold), they tweaked their name to “Century Arms International” instead of “Century International Arms” to avoid the misconception that these guns had been imported by… the C.I.A. Yep, seriously.

Other import marks I’ve seen on P6 pistols include PW Arms Redmond, WA:

and BTP New Ox, PA:

Surplus P6 pistols are still available in the secondary market, and are still a pretty good deal, though they’re no longer quite as available or as big a bargain as they were in the early 2000s. I see them going now (in 2017) for between $375-$450 in good condition, which is still hundreds of dollars less than their P225 counterparts. For reference, on the day I wrote this article, there was a P6 on GunBroker with a “Buy It Now” price of $380, and another one on a local gun website with a $400 asking price. There are still plenty of examples out there in good condition, as police service pistols generally have more holster wear than anything, and are carried often but rarely fired.

Surplus P6 pistols are still available in the secondary market, and are still a pretty good deal, though they’re no longer quite as available or as big a bargain as they were in the early 2000s. I see them going now (in 2017) for between $375-$450 in good condition, which is still hundreds of dollars less than their P225 counterparts. For reference, on the day I wrote this article, there was a P6 on GunBroker with a “Buy It Now” price of $380, and another one on a local gun website with a $400 asking price. There are still plenty of examples out there in good condition, as police service pistols generally have more holster wear than anything, and are carried often but rarely fired.

Updating a SIG P6

If you’re fortunate enough to get a good deal on a SIG P6, there’s nothing wrong with leaving it completely stock and just enjoying it. As with any pre-owned SIG, I’d at recommend at a minimum cleaning it, lubricating it, and replacing all the springs as a preventative measure. So if you like the heavy police-weight trigger pull, original plastic grips, Von Stavenhagen sights, and don’t plan on shooting large-grain hollow-point rounds, you’re good to go out of the blue plastic box.

But with some minor tinkering, you can easily (and non-permanently) add a small handful of updates to your P6 to transform it into a sweet little single-stack, easy-to-conceal, great-shooting West German classic that’s as good as (or even better than) a stock P225… at far less than current P225 prices.

P225-A1 Parts will NOT Work in a P225 or P6

When looking to upgrade a SIG P6, the good news is that any SIG P225 part or accessory will fit. But don’t go filling your online shopping cart just yet. When searching for P225 parts, you’re certain to come across parts for the SIG P225-A1 — which is a totally different pistol than the original P225.

Other than sights, I can’t think of any P225 parts shared by the P225-A1 — and that includes the grips. The SIG P225-A1 is actually much closer to a SIG P239 than the original P225, and P225-A1 parts do not fit on a classic P225 or a P6. I often see parts mis-marked online as P225 parts, when they’re actually P225-A1 parts. Make sure it’s a true classic P225-compatible part before ordering.

Reduce Trigger Pull Weight with a Standard Mainspring

The first update I suggest is to replace the heavy German police mainspring with the lighter OEM mainspring found in the P220, P225, P226, P228, and P229. Over the years, there have actually been three versions of SIG’s classic P-Series hammer strut / mainspring assembly, and all P6 pistols would have originally shipped with the “old-style” pre-1999 version.

SIG P6 pistols originally came with the “old-style” P-Series hammer strut assembly

You can swap out just the spring itself (SIG Sauer Part# MAINSPRING-2) or replace the old assembly with one of the updated versions (which is what I usually do). This article explains all three hammer strut / mainspring assembly versions and gives you all the part numbers you’ll need to update yours. My hammer strut / mainspring article also explains that when upgrading to one of the newer hammer strut assemblies with a plastic mainspring seat, the original plastic P6 grips will need to be slightly modified on the interior (just remove a little plastic) to fit properly. But if you’re also planning to upgrade the grips on your P6, newer grips are compatible with the newer mainspring seats without any modification.

If you’re considering replacing the mainspring with something lighter than the OEM weight, like a Wolff 17 lb spring, be sure to test for light primer strikes before you rely on your P6 for anything other than target practice. My personal preference is to always go with factory spring weights.

Replace the Trigger… If You Want One and Can Find One

While the P220, P226, P228, and P229 all share the same standard P-Series trigger, that trigger won’t fit in a P225 or P6. The P225/P6 trigger is only used on the P225 and P6 (again… not on the P225-A1), but for those (like me) who like their trigger finger pad a bit closer to the grip, SIG also offered a reduced-reach trigger for the P225 that works on a P6 (bottom-left corner in the photo below). The slimmer “reduced-reach” P225 triggers were discontinued long ago, and are now difficult to locate, but if you’re lucky you might be able to find one. Aftermarket P225 triggers will also fit a P6.

Classic P-Series trigger comparison

Pop In an SRT Kit

There are few upgrades to a classic West German SIG that make a bigger difference than installing a Short Reset Trigger Kit (SRT Kit). The word “trigger” is confusing in this case, and I explain in this rant that SRT kits have nothing to do with the trigger. But confusion aside, I highly recommend installing an SRT Kit (my video shows how easy it is to do yourself) to greatly reduce the reset on your P6’s action and make it much easier to shoot. Any of the P-Series SRT kits will fit in a P6, including the P220 SRT Kit which is sold as a separate part number as the P226 / P229 kit. I recommend the P220 SRT Kit if you can find one, since it also includes an updated decocker lever that prevents frame damage and fits the P6 just fine.

Decide Whether to Modify your Feed Ramp

As mentioned previously, the feed ramp width and angle on P6 pistols prior to June 1989 is different than on the P225, which means it sometimes doesn’t feed large (124-grain) JHP rounds reliably. If you’re planning on shooting larger hollow-point rounds, I recommend either replacing the barrel with an OEM P225 barrel (which are now almost impossible to find) or sending your barrel to a gunsmith with P6 feed ramp modification experience.

Get a Grip on your P6

The final “must-have” when upgrading a SIG P6 is a set of modern grips. There’s certainly nothing wrong with the original plastic P225/P6 grips, especially if you like that classic look. Any aftermarket P225 (but not P225-A1) grip will fit a P6, and there’s a wide selection available. But fitting a set of these Hogue G10 checkered grips on a single-stack P6 makes it feel perfect to me. And they look as good as they feel.

Hogue G10 checkered grips on a SIG P6

Try a Solid Guide Rod

I don’t consider a solid guide rod a “must have” upgrade, but I personally like them. The P6, like most early SIGs, originally came with a hollow metal guide rod. The basic thinking behind a solid metal guide rod is that it slightly increases overall weight which slightly reduces recoil, as well as shifts a slight amount of additional weight to the front of the pistol to slightly reduce muzzle rise and/or slightly help you get back on target for follow-up shots. The difference is slight and some shooters can’t tell any difference, while others swear by solid guide rods. I’m somewhere in the middle. I can tell a slight difference and have convinced myself I like it better. They’re not expensive, so it’s easy to try them out to see if you prefer them, too.

SIG P6 with stainless steel solid guide rod

Like its trigger, the P225/P6’s guide rod isn’t shared with any other SIG pistol. And again, the P225-A1 isn’t the same as a classic P225 so a P225-A1 guide rod won’t fit. I recommend this black nitride finished P225 solid guide rod, which is also available in polished steel if you prefer that look.

Other P6 Modifications

Of course, there are plenty of additional modifications you can make to your P6, just as there is with any gun. If you plan to use your P6 as an EDC, a decent holster and a set of quality night sights like these Trijicon HDs (my personal fav) are fantastic. You could even install an updated take-down lever if you prefer that look (later P225s shipped from SIG with the updated takedown lever), though many love the P6 for its classic lines and prefer to keep the controls original. It’s your gun, so do with it what you want. You can also look to my West German to Legion Specs article for other upgrade ideas… most of which also apply to a West German P6. But the P224 slide catch and decocker used on SIG Legion line pistols will not fit on a P225 or P6.

Stock Up on Magazines

While not actually a modification, while I have your attention I recommend grabbing a few extra P225/P6 magazines. Again, the P225-A1 magazines are totally different and won’t work with your P6. Only P225 or P6 magazines work on a true P225 or P6. The majority of West German surplus P6 pistols came in a blue plastic box with two P6-marked magazines, but thousands of magazines were made and are still out there. SIG isn’t making any more of them, so check for them on eBay or GunBroker while they’re still easy to find. Also, keep in mind that friends don’t let friends buy ProMag. Stick with OEM mags for your P6.

I have it on good authority that the folks at PH Brass and Bullets still have a number of surplus OEM P6 mags for sale. Ask for Patrick and tell him “Ferrari Steve” sent you, and you’ll get a great deal.

Original P6 8-round magazines

Is a SIG Sauer P6 Right for You?

If you’re looking for a compact, comfortable, concealable, great shooting, reliable pistol with West German heritage, you might enjoy a SIG P6. Some “purists” claim that the fit and finish on the commercial P225 is superior to the P6, but that hasn’t been my experience. Ignoring the markings and notched hammer, a non-abused P6 with a P225 mainspring and updated feed ramp angle looks, feels, and operates exactly like a P225. They were both made in the same Eckernförde facility by the same staff using the same equipment (Swiss-made P225 pistols also exist, but that’s a story for another day). Surplus P6 pistols are now slightly more expensive than when they first began to arrive in the US, but I still consider them a bargain… and have yet to meet a P6 owner who feels otherwise. They work just fine out of the box, but with a minor amount of tinkering they can become something truly special. Discontinued parts and accessories are slightly harder to find than for other classic P-Series models, but maybe that adds to the charm of owning a gun often referred to as the “baby P220.”

Is the SIG Sauer P6 right for you?

As always, I welcome your questions, comments, and feedback below! For more discussion of all things SIG Sauer, join us in the SIG Sauer Legion Facebook group.