Step 1: Update Your P226 Springs

If you purchase a certified pre-owned SIG Sauer pistol (commonly referred to as a “CPO SIG”), this step was probably done for you by a SIG factory technician. But if you pick up a used P226 in the secondary market (GunBroker, pawn shop, private sale, etc.) it’s difficult to know how many rounds have been fired through the gun before it got to you. New springs are very cheap insurance, so they’re always among the first things I replace on a West German P226, starting with the recoil spring.

P226 Recoil Spring

P226 recoil springs are coiled “tighter” on the end that faces away from the muzzle, so that the spring will grip the recoil spring guide (aka guide rod) more tightly on that end and stays in place during firing. But I can’t count the number of times I’ve field stripped a used P226 and found that the recoil spring was installed backwards. The gun usually still operates, but it’s definitely sub-optimal. Current versions of SIG’s recoil spring are painted on the tighter end, so it’s easier to tell which end faces away from the muzzle (that’s the end where the guide rod inserts). The factory P226 9mm recoil springs are painted orange, indicating a 16 lb spring weight. Different models and calibers will have different colors, indicating different sizes and weights. The P226 .40 cal spring, for example, is painted green… and also happens to be the correct spring for a P220 .45 cal.

If you field strip a used West German P226 at a gun shop and find an orange painted recoil spring, that’s not the original spring. But unless you’re going for museum collectibility, that’s not a bad thing — it means someone probably maintained the gun. Here’s an original P226 9mm recoil spring next to a current one (the only real difference is the paint):

SIG recommends that the P226 recoil spring be replaced every 5,000 rounds. But they’re cheap (you can pick up three of them for $20 direct from SIG), so I tend to replace it every 2,500 to 3,000 rounds. And I always replace it when I purchase a non-CPO used SIG, and you should, too. Plenty of heavier and lighter aftermarket springs are available, but I never use anything but the proper, 3 coil, factory-spec spring, part number SPRING26.

P226 Trigger Bar Spring

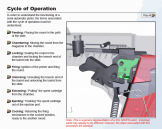

One of the earliest updates to the P226 pistol was the trigger bar spring. If you have a West German P226, then there’s a very good chance it still has the original “bent” style trigger bar spring that looks like this:

As opposed to the updated “looped” style that looks like this:

There’s nothing functionally wrong with the older bent style — it still works fine and helps the trigger reset after firing. But the older bent style rubs against the frame (you can see some light wear from the spring movement on my P226 in the first photo above), so SIG updated the design to the looped style to avoid that wear. Some argue that that the looped style provides a more “affirmative” trigger reset, but I’ve personally never really felt that much difference between the two.

SIG recommends replacing the trigger bar spring every 10,000 rounds. The original bent version’s part number is SPRING36. It’s been discontinued, but you might be able to find some new old stock online if you want to stay completely original. The updated looped version is SPRING37, and can be found online for around $5.

Never Use Original West German P226 Grips with a Looped Trigger Bar Spring

This is extremely important. If you switch to the updated trigger bar spring, the original West German P226 grips cannot be used without modification. Using the original early P226 grips with a looped trigger bar spring will cause the spring to unhook during firing and prevent the trigger from resetting. This would be terribly inconvenient in a gun fight. This photo shows an original West German right-side factory P226 grip (on the left) next to a current-gen factory P226 grip (on the right), with their corresponding trigger bar springs:

Note that both versions of the grip are “relieved” to fit their vintage trigger bar spring without interfering with their movement. The older right-side grip binds against the looped spring, and will cause it to malfunction. If you want to keep the original grips and run the updated the spring, you’ll need to use a Dremel tool (or something similar) to gently cut away some of the plastic in the right-side grip to allow the looped trigger bar spring to operate freely.

Or you can do what I do: upgrade to newer style grips (which happens to be the next step) which have plenty of room for the looped spring.

Other Springs

There are other springs in a P226 that you might want to consider replacing, including the mainspring assembly. But I discuss that in a later step, as part of upgrading the trigger and action.

Get Your Springs with a P226 Parts Kit

For around the cost of a three-pack of recoil springs and one trigger bar spring, you can pick up a complete P226 9mm Parts Kit direct from SIG. The kit contains the most common replacement parts for a P226: decocking lever spring, slide catch lever spring, trigger bar spring, recoil spring, slide roll pins, and a set of four grip screws. SIG recommends that the decocking lever spring and slide catch lever spring be replaced every 10,000 rounds, and the slide roll pins every 5,000 rounds. I always have a parts kit on hand — it’s cheap insurance for $26.